Goods received

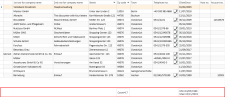

Items | Goods received

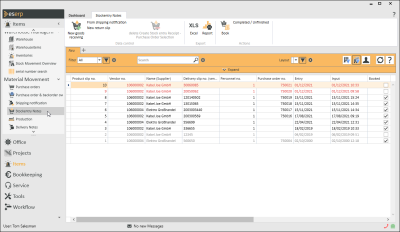

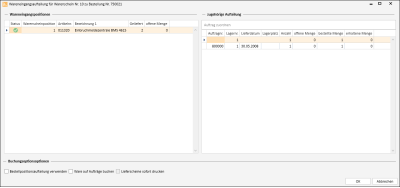

Deliveries from vendors are recorded and the stock entry slips and return notes that have already been recorded are displayed using the Items | Goods received menu command.

Deliveries made in connection with a purchase order can be accounted for in goods received, as can goods received that do not have any reference to a purchase order.

A stock entry cannot be made for items that are in the inventory process. This applies to an annual inventory, which completely blocks warehouse management, as well as to any othe inventory that concerns the particular item.

Items | Goods received | View goods received authorization is required for this menu command.

Items | Warehouse management | Edit stock entries authorization is required to edit a stock entry.

Goods received status

The status of stock entry slips and returned goods slips is indicated by the color:

-

Booked (shown in black)

-

Not booked (shown in red)

-

Completed (shown in gray)

Available information

Some information about the stock entry is shown in the list. Additional columns can be shown using the column editor.

Stock entry note no.

Unique consecutive stock entry number. When a stock entry note or return slip is created, the number is drawn automatically from the EIN number range.

Vendor no. and name (vendor)

The vendor information is drawn from the vendor master data (Office | Vendors).

Delivery slip no. (Vendor)

This is the delivery slip number assigned to the process by the vendor.

Personnel no.

The personnel number of the employee who created the stock entry note.

Received

The date on which the goods were received. The current date is set by default.

Input

The date and time when the process was recorded. The current date and time are set by default.

Purchase order no.

The number of the associated purchase order that was sent to the vendor.

Booked

This option is activated when all the items in the goods received have been or can be booked into a warehouse.

Warehouse no.

The warehouse number selected on the Items | Stock entry | Details tab. The Main warehouse is always entered here by default. This can, however, be edited.

Main warehouse

The Main warehouse is specified under Settings | Items | Warehouse management | Settings - 'General' area.

Booking date

Date of booking the stock entry.

Checked

This option indicates whether the goods received are correct (according to the purchase order) and the invoice has been released for payment.

Completed

If you activate this option, the stock entry is completed.

This option can be activated / deactivated using the Completed / Uncompleted button in the toolbar.

Office branch no.

The office branch (office branch no.) for which the stock entry note was recorded is displayed here.

Return slip to Commodity slip

This option is activated for a Return delivery slip.

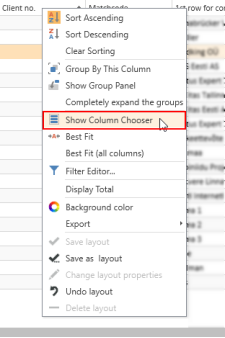

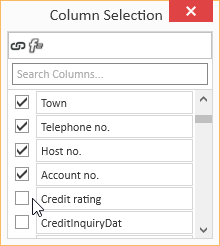

Column selection / Column editor

The columns to be displayed in a Data Grid can be set using the Column Selection dialog. To open Column Selection, right click on the table column header and choose Show Column Editor from the context menu.

In the Column selection window, you can show the desired columns by activating the option in front of the column name.

Deactivate the check box in front of the column name to remove the column from the list view.

To save the list view layout, right click on the column header and select Save layout from the context menu.

Move columns / Change column order

Each user can set the column order individually. To move a column, click on the column and hold down the left mouse button, drag it to the desired position between two columns and release the mouse button (drag and drop).

Suitable locations for inserting a column are marked with two colored arrows.

Optimum width

Adjusts the column width to automatically match the contents. Right click on the column header and select Optimum width from the context menu.

Use the Save layout function to permanently store the changed column width.

If you do not save the Layout after changing the column width, the column width will be reset when you restart the module.

Optimum width (all columns)

Adjusts the column width to automatically match the contents for all columns. Right click on the column header and select Optimum width (all columns) from the context menu.

Use the Save layout function to permanently store the changed column width.

If you do not save the Layout after changing the column width, the column width will be reset when you restart the module.

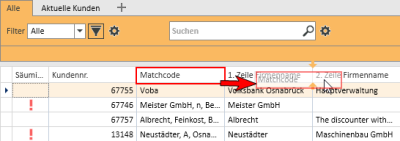

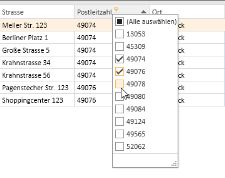

Column filters

You can use column filters to display only certain data sets from extensive lists.

You can use the column filters for example to display all the client data sets for a particular ZIP code. Only the ZIP codes that are already recorded for the client data sets will be displayed.

To filter the data sets, click on the desired column (for example ZIP code) and on the filter icon ![]() there.

there.

You will now see a list of all the recorded ZIP codes.

You can now select one or more values for the filter. There are also additional filters available (all, user defined, empty, not emptry).

If a filter is active for a column, this is indicated by the colored filter icon ![]() in the column header. Click on the icon to edit the filter.

in the column header. Click on the icon to edit the filter.

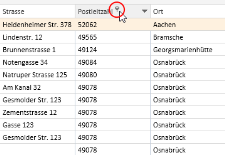

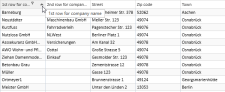

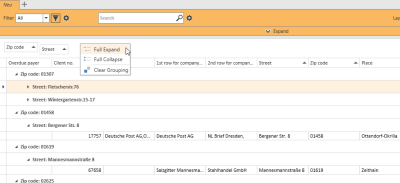

Sort order

The values in a column can be sorted in ascending or descending order by clicking on the table column header.

You can sort rows without changing existing sort conditions as follows:

-

Press and hold down the Shift key and click on the column header until an up or down arrow appears

-

Right click on the column header and select Ascending order or Descending order from the context menu.

In the above example, the list is sorted by Zip code (ascending order) and additionally by Street (descending order). Thus, if there are several entries with the same Zip code, these entries will be sorted according to the Street field.

To remove a column from the sort criteria, press and hold down the Ctrl key and click on the column.

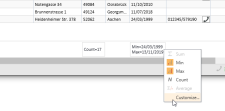

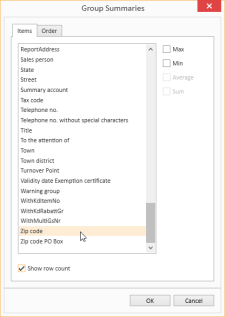

Column summaries

A column summary can be displayed below each column in the list.

To configure this column summary, right click on the column header and select Show Sums from the context menu.

A Totals field is now shown below the list. Right click in this field to select the value to be displayed for this column.

You can use the Customize... context menu command to make more detailed settings for the column summaries, including setting the Sort order and labeling when there are several sums.

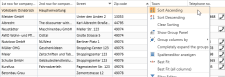

Groupings

To group according to one or more columns, proceed as follows:

Method 1

- Right click on the column header and select Show grouping field from the context menu.

- Drag a column header into the Grouping field.

- You can drag additional columns into the grouping field to further subdivide a grouping.

- To remove the grouping, drag the column header from the group selection field and drop it back in the list or select the Remove grouping command in the context menu.

Method 2

Right click on the column header and select Group columns by from the context menu. You can now select whether to use the Standard grouping or grouping according to Initial letters.

To remove the grouping, right click on the column header or the particular column in the Group Selection field and select Remove Grouping from the context menu.

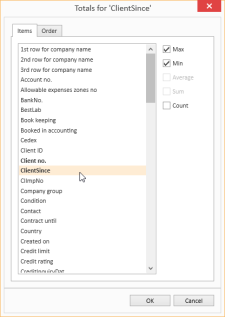

Grouping summaries

Summaries can be displayed for individual groupings.

To do this, right click in the column header in the Group Selection field and select Group Sum Editor from the context menu.

You can now define criteria for a Group Summary in the Group Selection dialog. You can use the Show number of rows option to display the number of data sets in a group.

Sort according to Grouping summaries

When a data grid has been grouped and a Grouping summary has been defined, the grouped data grid can also be sorted according to the values in the Grouping summary. Right click on the column header that is used for the grouping and select Sort by Group sorting from the context menu.

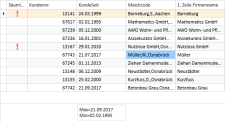

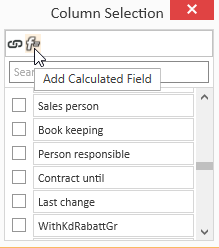

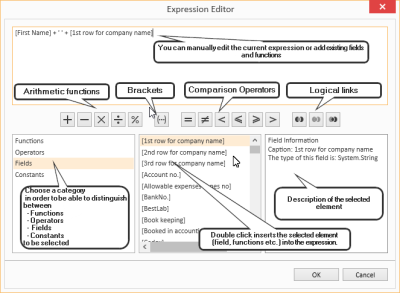

Calculated Fields

You can create Calculated fields in the Column editor. To do this, open the Column editor and click on the Add calculated field button.

First, you will be asked for a field name. Enter the header for the Calculated Field in the box. When you click OK to confirm the dialog, the Expression editor opens.

You can find a list of the functions and operators under Functions in Calculated fields.

To later edit the Expression, right click on the table column header of a Calculated Field and select Edit Expression from the context menu.

Iif(IsNullOrEmpty([Vorname]), [1. Zeile Firmenname], [Vorname] + + [1. Zeile Firmenname])In this example, the First name and Company 1 fields are combined into one field with a space between them, but only if the First name field is filled out. Otherwise, only the Company 1 field is output.

Field Background color

Data fields that meet certain conditions can be highlighted with a Background color.

To set Background colors for individual fields, right click on a column and select Background color from the menu.

You can now define a new rule. All the fields that match this rule will then be highlighted in the selected color.

The pencil icon opens the Expression editor. You can create more complex expressions with this editor. Also see Calculated Fields.

When you have successfully created a rule, close the window by clicking the OK button. The rule will be applied when you refresh the View.

Rule: [NoEmployees] < 30

Color: #FF009DFF

This rule colors all fields in the Client no. column blue if the number of employees entered in the corresponding data set is less than 30.

Using and Managing layouts

Right click on a column to open a context menu where you can access the Layout settings.

Load Layout

The Load layout command displays all the layouts that you have already created.

You can easily switch to another Layout here.

Save Layout / Save Layout As

When you Save Layout, the current View will be saved in the currently open Layout. All Expressions, Calculated Fields and Sort Groups will be included in this Layout and can be applied as required.

You can use the Save Layout As command to save the current View as a new separate Layout.

Specify the Layout properties for this.

Edit Layout

If you want to change the properties of the current Layout, select Edit Layout Properties from the menu. The Layout properties window opens. You can make the changes that you want here.

Reset Layout / Delete Layout

If the edited Layout is not what you want, you can undo the changes you made and revert to the original Layout by selecting Reset Layout from the menu. You can also use the Delete Layout command in the menu to delete a Layout entirely if you no longer want it.

Functions / Toolbars

Various functions are provided in the toolbars (ribbons / ribbon bars) above the tabs.

The toolbar structure depends on the current module / tab.

Some toolbars are only shown when you edit certain fields, such as the Text toolbar when you edit rich text fields.

'Goods receipts' area

'Data control' area

![]() New stock entry

New stock entry

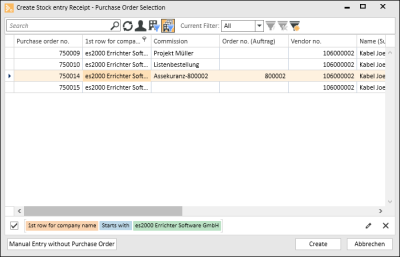

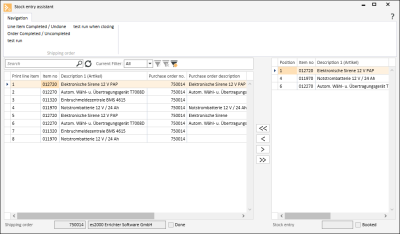

The following steps are required to create a stock entry on the basis of a purchase order:

Create stock entry

-

Open the Items | Goods received menu command.

-

Click on the

New stock button in the Navigation toolbar.

New stock button in the Navigation toolbar.The Create goods received - Select purchase order window opens.

-

The List functions for filtering and searching are provided in the selection of purchase orders.

-

You can also create a stock entry without assigning it to a purchase order by clicking on the Record manually without purchase order button.

-

Select the purchase order for which you want to create a stock entry and then click on the Create button.

Call orders are not shown in the purchase order selection.

-

The stock entry assistant opens. The line items in the selected purchase order are shown in the list on the left. The stock entry line items are shown in the list on the right.

Transfer the desired line items from the purchase order to the stock entry using the

button.

button.You can use the

button to transfer all the line items in the purchase order into the stock entry.

button to transfer all the line items in the purchase order into the stock entry.The quantities present in the purchase order will aslo be transferred and can now be adjusted to the delivered quantities.

When selecting the purchase order line items for transfer into the stock entry (stock entry assistant), the PPrice (purchase price) field of the purchase order line item is transferred into the PPrice field of the corresponding stock entry line item.

You can delete all / individual line items from the goods received slip again using the

/

/  buttons.

buttons. -

Once the line items have been transferred, click on the

top right in the window to close the stock entry assistant.

top right in the window to close the stock entry assistant.Before the table of stock entry line items is saved, the value from Net price converted using the currency code is written into the PPrice field.

-

A stock entry data set is created and the Items | Stock entry | Details tab opens. Specify the further details.

-

Select the Items | Stock entry | Line items tab. The individual line items can be viewed and edited here (warehouse, quantity, price, serial numbers).

-

The stock entry can now be booked using the

Book button in the Navigation toolbar.

Book button in the Navigation toolbar.

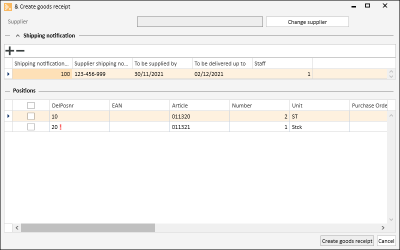

From shipping notification

A stock entry can be generated from a Shipping notification using the From shipping notification button. Further shipping notifications can be added to this.

The Create stock entry window opens.

Vendor

The vendor to which the shipping notification is assigned is shown here.

If line items from different vendors are present in the shipping notification on the Items | Shipping notification | Line items tab or are assigned for a line item in a purchase order, the vendor will not be shown here.

Change vendor

You can use the Change vendor button to select a different vendor.

All selected line items and shipping notifications will be reset if you select a new vendor.

'Shipping notification' area

The shipping notifications to be used for the stock entry are displayed in the Shipping notification list.

You can add further shipping notifications with the ![]() button, and remove individual shipping notifications from the list again with the

button, and remove individual shipping notifications from the list again with the ![]() button.

button.

You can mark several shipping notifications in the list on the Shipping notification overview page under Items | Shipping notification by holding down the Ctrl key and clicking on them, and then use the Create stock entry function to create a stock entry for the marked data sets.

'Line items' area

The line items in the shipping notification are shown in the list.

If a stock entry has already been created for the shipping notification, only the line items for which a stock entry has not yet been created will still be shown.

Activate the option in front of each line item that you want to include in the stock entry and then click on the Create stock entry button.

The Items | Goods received | Details tab opens for further editing of the stock entry.

New return slip

A return slip can be created to return items in a shipment of goods received to the vendor (incorrect quantity or item, damaged, etc.).

To be able to create a return slip for goods received, at least one item of the goods received must still be present in the delivery warehouse with a quantity greater than 0. If With actual purchase prices is being used, a check is made to see if the corresponding items are available in the warehouse.

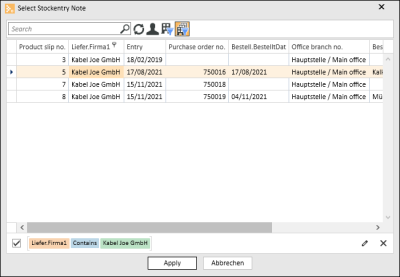

Create return slip

-

Open the Items | Goods received menu command.

-

Click on the New return slip button in the Navigation toolbar.

-

The Select goods received slip window opens.

The List functions for filtering and searching are provided in the selection of goods received slips.

-

Select the goods received slip for which you want to create a return slip and then click on the Apply button.

-

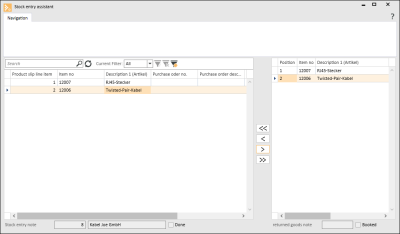

The goods received assistant opens showing the line items of the goods received slip.

-

Transfer the desired line items from the stock entry note to the return slip using the

button.

button.You can use the

button to transfer all the line items in the stock entry note to the return slip.

button to transfer all the line items in the stock entry note to the return slip.Grayed out line items cannot be transferred to the return slip as the required quantity is not available (already delivered, no warehouse stock).

You can delete all / individual line items from the goods received slip again using the

/

/  buttons.

buttons. -

Once the line items have been transferred, click on the

top right in the window to close the stock entry assistant.

top right in the window to close the stock entry assistant. -

A stock entry data set is created and the Items | Stock entry | Details tab opens. The Return slip option is already activated. Specify the further details.

-

Select the Items | Stock entry | Line items tab. The individual line items can be viewed and edited here (warehouse, quantity, price, serial numbers).

-

The return slip can now be booked using the

Book button in the Navigation toolbar.

Book button in the Navigation toolbar.

![]() Delete stock entry

Delete stock entry

A stock entry marked as completed can be deleted using this function. A security prompt is displayed before actual deletion (Delete data set? Yes / No). The stock entry is not deleted until you confirm the query by clicking on the Yes button.

'Export' area

![]() Excel

Excel

You can save the displayed data as a list in MS Excel format (*.xlsx or *.xls) using this button. The current column, filter, and search settings are considered when the data is exported.

![]() Report

Report

Reports can be used to print out or send the displayed information for an address or process. The reports that are registered for the current program point are displayed when you click on the Report button.

Also see Registration

![]() Copy address

Copy address

Copies the current address to the clip board. The address that you copied can then be inserted as text from the clip board into any application, or you can use the Insert address function to insert the address into an eserp address form.

'Actions' area

![]() Book

Book

A prepared stock entry or return slip is completed and the warehouse booked using the ![]() Book button.

Book button.

Items that do not exist in the warehouse can be created automatically when a stock entry or return slip is booked. For this to happen, the Create warehouse items when receiving option must be activated under Settings | Items | Stock movement | Settings | General - 'General' area.

Book stock entry note / return slip

-

Select an unbooked stock entry note / return slip from the list.

Unbooked data sets are shown in red.

-

Click on the

Book button in the Navigation toolbar.

Book button in the Navigation toolbar. -

The Stock entry distribution window opens. The line items in the stock entry are displayed in the left hand list (Stock entry line item) When you mark a stock entry line item, the associated distribution (warehouse / order) is displayed in the right hand list.

If there are line items referring to an order listed under associated distribution, Booking options are displayed below the lists.

Use purchase order line item distribution

The warehouse distribution of the stock entry is determined by the warehouse data in the purchase order.

Book goods to orders

The goods ordered for orders are booked to the orders through delivery slips.

Print delivery slips immediately

This option can be activated if the Book goods to orders option is activated. The corresponding delivery slips are printed out when this option is activated.

After a stock entry has been booked to the order, a check is made to see if the stock entry only applied to one order, which will also only create one delivery slip in the background.

If this is so, the delivery slip number and order number will be entered in the stock entry note on the Items | Stock entry | Details tab.

Manual assignment of delivery line items

If the number of one or all line items is less than that required for the distribution, manual distribution of the quantities in the distribution in the list is required before the stock entry can be booked. No residual quantities must remain for the quantities assigned manually.

The corresponding line items are marked with the

icon in the Status column of the Stock entry line items list. The reason why the stock entry cannot be booked will be displayed when you hover the mouse pointer over the icon.

icon in the Status column of the Stock entry line items list. The reason why the stock entry cannot be booked will be displayed when you hover the mouse pointer over the icon. -

When all the line items have been distributed correctly, click on the OK button.

Instead of the net price (which can also be in a foreign currency), the purchase price (equals the price in the local currency) is entered in the associated delivery slip line items and in the Order materials (MaEKProj field) when the stock entry is booked to an order.

Also, the supplied serial numbers or none at all are assigned to the items first. A message indicating that more items were delivered than the serial numbers recorded in the stock entry is displayed if necessary.

When a stock entry is booked, the item data for the individual line items is taken from the calculation folder instead of from the item master data.

No further bookings can be made to completed orders.

A message is displayed if not all of the line items can be booked. Also, a check is made before booking to see if an inventory is running. If there is, stock movements cannot be made.

Warehouse consideration when booking

Warehouse consideration when booking

Order in which the warehouse information is considered when booking stock entries to order purchase orders.

-

The warehouse stated on the Items | Stock entry | Line items - 'Items' area

tab-> individual line item in the stock entry -

The warehouse stated on the Items | Stock entry | Details - 'Details' area tab,

-> Main set of stock entry -

The warehouse stated in the order purchase order line item, i.e. the warehouse that was included from the purchase order.

-

Main warehouse

If the goods are booked directly to the order, the warehouse information in the stock entry is ignored on principle. Unless the goods are distributed manually and incompletely. In this case, the undistributed goods are booked to the warehouses in the following order:

-

Details stated on the Items | Stock entry | Line items - 'Items' area tab

-

Details stated on the Items | Stock entry | 'Details' area tab

-

Main warehouse

Main warehouse

The Main warehouse is specified under Settings | Items | Warehouse management | Settings - 'General' area.

What is the significance of the warehoouse stated in the main set of the stock entry note?

If the goods are incompletely delivered, the delivered goods can be assigned manually. If not all of the delivered goods are distributed or an overdelivery is recieved for a purchase order, a check is made in the following order to see if a warehouse has been recorded and the remainder is booked to it:

-

Items | Goods received | Line items - 'Items' area

-

Items | Goods received | Details

-

Main warehouse

Average purchase price calculation on booking

The average purchase price can also be calculated when the stock entry is booked if the When booking stock entry option under Settings | Items | Item management | Settings - 'General' area is activated.

If it is, the average purchase price is calculated during the booking process.

The value in the PPrice field in the stock entry line items is also accessed for the calculation of the average purchase price.

When the booking has completed successfully, the Warehouse booked option on the Items | Stock entry | Line items tab will be activated.

The warehouse stock level can be set through booking a stock entry, and it is also possible to create warehouse items.

-

Completed / Uncompleted

If Goods received are completed, they can be marked as Completed. The Completed status can be used to filter the goods received to show only the uncompleted goods received in a list, for example.

The status of the Completed option is shown in the list view and in the Items | Goods received | Details - Details area.

You can activate or deactivate the Completed status using the Completed / Uncompleted button.