Details

Items | Warehouse items | Details

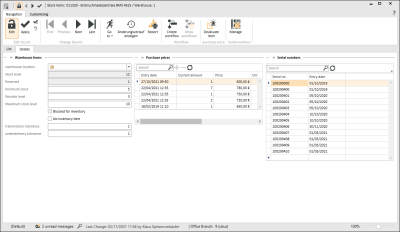

Further information about the stocks of a warehouse item can be recorded on the Items | Warehouse items | Details tab.

The Item number, Item description 1, and the Warehouse number for the warehouse item are shown in the tab header.

'Warehouse items' area

Warehouse location

The location in the warehouse is displayed and can be edited here.

Warehouse locations are created for each warehouse on the Items | Warehouse | Details - 'Warehouse locations' area tab.

If the Existing warehouse locations only option under Settings | Items | Warehouse items | Settings - 'General' area is activated, only warehouse locations that have already been created can be selected. A check will not be made to see if the warehouse location has been created in the warehouse If this option is deactivated.

The quantity of an item in the warehouse is shown in the Stock field. The stock quantity cannot be edited as the stock level can only be affected by goods received, delivery slips, or the inventory

Reserved

The quantity of reserved items in the warehouse is displayed here.

Minimum stock level / Reorder level / Maximum stock level

You can enter a minimum, reorder, or maximum stock level. You do not have to make an entry.

These fields must be completed, however, if purchase orders (for which the warehouse stock level is checked or considered) are to be created automatically.

The Reorder level is considered and the stock level then compared with it when purchase orders are generated for the purpose of adding stock to the warehouse. This field is also displayed in the Warehouse stock level dialog.

If an item in a purchase order that considers the warehouse is found to be below the maximum stock level, the difference between the item stock level and the maximum stock level will be added into the purchase order.

If the minimum stock level is reached when goods are shipped out (there is a corresponding setting for printing / booking a delivery slip which can be activated or deactivated) only the difference between the quantity to be shipped out and the minimum stock level will be booked.

The minimum stock level can be undershot for reservations and for production if the Ignore minimum stock inventory when reserving or producing option under Settings | Items | Warehouse management | Settings - 'General' area is activated.

Blocked for inventory

If this option is activated, the item cannot be processed at the moment because an inventory (stocktake) is being performed.

Item not inventoried

If this option is activated, the item is ignored in an inventory (stocktackiing).

Overdelivery tolerance

Specify here the number of items that may be delivered above the maximum stock level. This tolerance is taken into account in automatic purchase orders in conjunction with pack quantities.

Underdelivery tolerance

Specify here the number of items that may be delivered below the minimum stock level. This tolerance is taken into account in automatic purchase orders in conjunction with pack quantities.

'Purchase prices' area

The various purchase prices charged for the item are listed in this area.

'Serial numbers' area

Requirements for serial number management

To manage the serial numbers of warehouse items it is necessary to set With serial number management to Complete under Settings | Items | Item management | Settings - 'General' area and to activate the With serial number management option for the item on the Items | Items / Services | Details II - 'Items' area tab.

The serial numbers recorded for the warehouse item are listed in the Serial numbers area.

The serial numbers in the list are for the warehouse to which the warehouse item is assigned. The item can be in stock with different serial numbers in other warehouses.

You can search for serial numbers in the list and use the other list functions (grouping, filters, column editor, etc.).

You can use the ![]() Manage function in the Navigation toolbar in the Serial numbers area to add / edit serial numbers.

Manage function in the Navigation toolbar in the Serial numbers area to add / edit serial numbers.

Functions / Toolbars

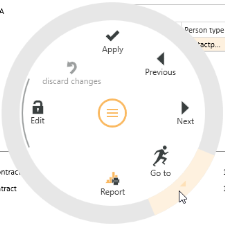

Various functions are provided in the toolbars (ribbons / ribbon bars) above the tabs.

The toolbar structure depends on the current module / tab.

Some toolbars are only shown when you edit certain fields, such as the Text toolbar when you edit rich text fields.

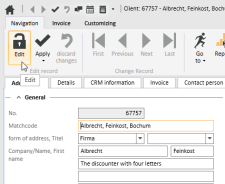

'Edit data set' area

![]() Edit

Edit

Click on the ![]() Edit button to switch the Form to Edit mode.

Edit button to switch the Form to Edit mode.

The usual Input elements are available in Edit mode.

If data has been changed and you close the form or change to another data set, a message will be displayed asking you if you want to save the changes or not.

Changes can be undone by clicking the ![]() Reject changes button as long as input has not been actively saved or the form has not been closed or the data set changed.

Reject changes button as long as input has not been actively saved or the form has not been closed or the data set changed.

Detail data sets can also be opened directly in Edit mode. To do this, deactivate the Do not automatically edit detail data option under Settings | General | General | Settings | System settings - 'Program behavior' area.

Also see Edit Data Set

![]() Apply

Apply

You can always actively save changes in the data by clicking the ![]() Apply button.

Apply button.

![]() Apply and close

Apply and close

You can save the changed data and close the entry form / module in one go with the ![]() Apply and close function.

Apply and close function.

![]() Reject changes

Reject changes

Changes can be undone by clicking the ![]() Reject changes button as long as input has not been actively saved or the form has not been closed or the data set changed.

Reject changes button as long as input has not been actively saved or the form has not been closed or the data set changed.

'Change data set' area

Each detail view contains a copy of the current list view for the module. This can be viewed on the List tab in the Detail view. This enables you to also navigate through the original list in the Detail View using the navigation buttons.

If a filter or search is active when you open the detail view, this will also be applied to the display on the List tab.

![]() First

First

Jumps to the first data set in the list. The sort order on the List tab is used.

![]() Previous

Previous

Pages back to the previous data set in the list. The sort order on the List tab is used.

![]() Next

Next

Pages forward to the next data set in the list. The sort order on the List tab is used.

![]() Last

Last

Jumps to the last data set in the list. The sort order on the List tab is used.

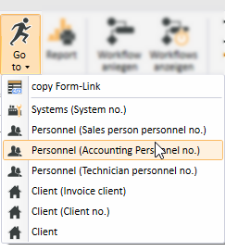

![]() Go to

Go to

There is a general Go to function in eserp that allows you to jump to the associated modules.

You can use the Go to function to jump to other modules that are connected to the current process.

You can jump directly from a Client data set to the Systems or Contracts for the Client.

The ![]() Go to button in the Navigation toolbar is used to execute the Go to function.

Go to button in the Navigation toolbar is used to execute the Go to function.

Click on the ![]() icon in the button to display the available Go to targets.

icon in the button to display the available Go to targets.

When you click on an item in the list, the corresponding module opens with the linked data set.

Go to in the Context menu

The Go to function is also available at many points in the program in the Context menu that is opened with a right mouse click.

![]() View change history

View change history

Program areas for which a detailed change history is to be recorded can be activated from Tools | Database logging. A report stating when data sets were deleted can be produced for each area. When the detail log function is activated, the report also states what kind of data sets were deleted.

This report is recorded in the report entry point Data set change history (Groups).

A report can be displayed from the Data set change history report entry point using the ![]() Show change history button. This function is also available in lists / tables via the context menu so that you can display the changes in the detail data sets.

Show change history button. This function is also available in lists / tables via the context menu so that you can display the changes in the detail data sets.

The Data set change history and Data set change history (Groups) report entry points are only shown when the license for esLog is present and the table RevGrup exists.

![]() Report

Report

Reports can be used to print out or send the displayed information for an address or process. The reports that are registered for the current program point are displayed when you click on the Report button.

Also see Registration

'Purchase price' area

![]() Depreciate item

Depreciate item

The purchase price of individual items can be depreciated using this function.

Items | Warehouse management | Warehouse items - Item depreciation authorization is required for depreciation of purchase prices.

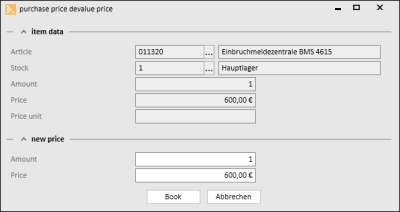

Depreciate item purchase price

-

Mark the purchase price to be depreciated in 'Purchase prices' area on the Items | Warehouse items | Details tab and then click on the

Depreciate item button.

Depreciate item button. -

The Depreciate PP window opens. Information about the item is shown in the Item data area.

-

Enter the new purchase price in the Price field in the New price area and the number of items to be depreciated in the Quantity field.

-

Click on the Book button to complete the depreciation process.

'Serial numbers' area

![]() Manage

Manage

Use the ![]() Manage button to open Serial number management / serial number recording for an item.

Manage button to open Serial number management / serial number recording for an item.

Requirements for serial number management

To manage the serial numbers of warehouse items it is necessary to set With serial number management to Complete under Settings | Items | Item management | Settings - 'General' area and to activate the With serial number management option for the item on the Items | Items / Services | Details II - 'Items' area tab.

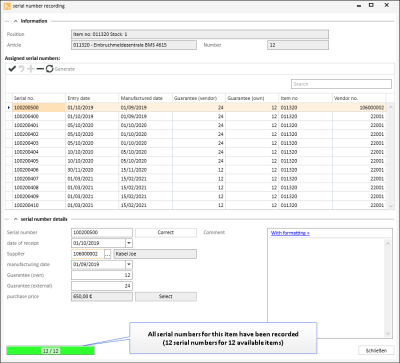

'Information' area

The details about the selected item are displayed in the Information area.

'Assigned serial numbers' area

The serial numbers already recorded are listed in the Assigned serial numbers area. You can create, delete, and save serial number entries, and generate consecutive serial numbers using the Navigator above the list.

'Serial number details' area

You can record the detail information for each recorded serial number in this area.

Correct

You can edit an already recorded serial number using the Correct button.

Record serial numbers

-

To enter serial numbers, click on the

button in the Navigator.

button in the Navigator.A new data set is created.

-

Now enter the serial number for an item.

If more than one serial number is sent with a shipping notification through eswawi, the additional serial numbers in the Additional serial no. field will be saved on import.

-

Enter the Date received and the Manufacture date.

-

The main vendor of the item is entered as the Vendor by default. This can be edited.

-

Enter the vendor's guarantee period in months (Guarantee (external)) and your own guarantee period (Guarantee (own)) if this is different.

-

You can also record a Remark in the information window

-

Save your entries by clicking on the

button in the navigator.

button in the navigator. -

Repeat the above steps to enter more serial numbers.

When all of your items have been given serial numbers, they are then saved automatically and can be recalled at any time.

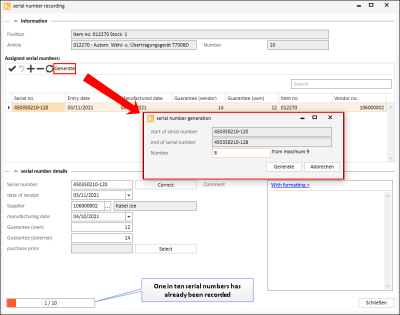

Automatic serial number assignment

Serial numbers can also be assigned automatically in eserp.

A vendor will usually supply items with consecutive serial numbers. For this reason, you can simply specify the starting serial number when entering serial numbers for goods received, for example. The subsequent numbers are then generated automatically.

Serial numbers up to the maximum number of existing items can be created automatically for goods received and for warehouse items.

The Generate button is provided in the Navigator above the serial number list for this purpose.

Enter the first serial number manually as the start number.

Then click on the Generate button.

The Generate serial numbers window opens, showing the maximum number of serial numbers to be created. The Number can be adjusted. You can view the Start serial number and the End serial number.

The Generate button records these numbers automatically.

There are two ways to increment automatically.

The maximum number of numerical places is usually cut from the end. The number cut is used as the minimum for the increment.

If the first digit in the cut number is a zero, formatting will be used. Otherwise, no formatting is used.

Example: 25 serial numbers are to be generated automatically.

With formatting

Start serial number 345 0815 - 07.

The digits 07 are cut and the serial numbers from 345 0815 - 08 through 345 0815 - 32 are created.

Without formatting

Start serial number 345 0815 - 107.

The digits 107 are cut and the serial numbers from 345 0815 - 108 through 345 0815 - 132 are created.

Start serial number 345 0815 - 7.

The digit 7 is cut and the serial numbers from 345 0815 - 8 through 345 0815 - 32 are created.

![]() Close

Close

Closes the current form / module.

A message will indicate if there are any unsaved changes.

You can then decide whether to save the changes (Yes), reject the changes (No) or cancel the Close command (Cancel).

The Customize (0110250) license is required for customizing.

The optional esCustomize allows the following control element properties to be adjusted:

- The order and visibility of input and control elements

- The labeling of control elements

- The layout of control elements (color, text width)

- The brief hint text for control elements

- The data linking of control elements

It is also possible to create new fields and add them to the Form.

![]() Start customizing

Start customizing

Click on the ![]() Start customizing button to switch the current form to Customizing mode.

Start customizing button to switch the current form to Customizing mode.

The Form is always customized in the context of the current role that is being used (see Role assignment).

To find out how to change the role, please see: Role assignment.

General | Administration | General references - Customize forms authorization is required to customize forms.

Also see Customizing forms

Apply customizing from role

Click on the Apply customizing from role button to apply the customizing settings already defined for another role to the current form. A selection of the customizing properties defined in other roles is shown.

![]() Edit fields

Edit fields

You can edit certain properties (required field, font color, background color, default values) of the input fields in a form / module using the Edit fields function. Also see Required fields and Default values.

You can also create your own fields and user defined data packs, also see Create individual fields.

![]() Role management

Role management

This button opens management of customizing roles.

Customizing roles can be created and managed under Settings | General | Customizing | References | Customizing - Roles.

Functions when the Customizing process is running

Three additional buttons are shown after you start Customizing:

![]() Apply

Apply

This function saves the temporary customization and closes Customizing mode.

You must close and restart the program for the changes to be visible to the user.

![]() Cancel

Cancel

Use this button to Cancel the Customizing process. Customizing mode closes without saving the changes you made to the forms.

![]() Reset

Reset

This function resets Customizing and loads the default settings for the form. The reset is performed only after you have confirmed the query dialog that is displayed.

The current Customizing settings are deleted by the reset and cannot be retrieved.

General | Administration | Reset form customizing authorization is required to reset Customizing.